SIKAFLEX 591 WHITE 300ML 440GR

Couldn't load pickup availability

Sikaflex®-591

Sikaflex®-591 is a sealant based on Sika’s Silane Terminated Polymer (STP) technology. With its excellent resistance to harsh maritime weather conditions it can be used for a wide range of applications. Sikaflex®-591 exceeds common environmental and safety standards and sets a new ecological benchmark. Sikaflex®-591 meets the low flame spread standards (FTP Code, Part 5) set by the International Maritime Organisation (IMO).

ADVANTAGES

- IMO Approved

- Exceeds EH&S standards

- Free from isocyanates, solvents, PVC, phthalates and tin catalysts

- High elasticity

- Excellent weather stability

- Excellent workability and spatula properties

- Adheres well to a wide variety of substrates used in the marine industry

Jobs

Sikaflex®-591 is a multipurpose sealant designed for marine applications. It is suitable for elastic and vibration resistant bonds and for a wide range of interior and exterior sealing applications. Sikaflex®-591 adheres well to substrates commonly used in the marine industry. Sikaflex®-591 is not suitable for applications with Teak wood and plastics that are prone to stress cracking (e.g. PMMA, PC, etc.). This product is suitable for experienced professional users only. To ensure adhesion and material compatibility, tests with actual substrates should be performed.Packaging

|

Cartridge |

300 ml |

Product Details

HARDENING MECHANISM

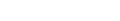

Sikaflex®-591 cures by reaction with atmospheric moisture. At low temperatures the water content in the air is generally lower and the curing reaction proceeds more slowly (see diagram 1).

Diagram 1: Curing speed for Sikaflex®-591

CHEMICAL RESISTANCE

Sikaflex®-591 is generally resistant to fresh water, sea water, diluted solutions of acids and bases; short-term resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, alcohol, concentrated caustic and mineral acid solutions or solvents.

Application

METHOD OF APPLICATION

Surface preparation

Surfaces must be clean, dry and free from grease, oil and dust.

Surface treatment depends on the specific nature of the substrates and is crucial for a long-lasting bond. Suggestions for surface preparation can be found in the current edition of the appropriate Sika® Pre-treatment Chart. It should be noted that these suggestions are based on experience and should be verified by tests on original substrates.

Application

Sikaflex®-591 can be processed between 5 °C and 40 °C, but variations in reactivity and application properties must be taken into account. The optimum temperature for substrates and sealant is between 15 °C and 25 °C. Sikaflex®-591 can be processed with piston, manual, pneumatic or electric extrusion guns.

In case Sikaflex®-591 may come into contact with a polyurethane, ensure that such products are cured or wait at least 24 hours before sealing.

Spatula and finishing

Tooling and finishing must be carried out within the skin time of the sealant. The use of Sika® Tooling Agent N is recommended. Other finishing agents must be tested for suitability and compatibility prior to use.

Removal

Uncured Sikaflex®-591 can be removed from tools and equipment with Sika® Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin must be washed immediately using hand cleaning wipes such as Sika® Cleaner-350H, or a suitable industrial hand cleaner and water. Do not use solvents on skin!

Le spedizioni per l'Italia avvengono in 2-6 giorni lavorativi. Il costo è di €9,99 per i pagamenti effettuati con carta e di €14,99 per pagamenti con contrassegno.

Le spedizioni per i paesi UE avvengono in 4-9 giorni lavorativi. Il costo è di €30. Non è possibile effettuare il pagamento con contrassegno.

Le spedizioni per i paesi Extra UE avvengono in 6-10 giorni lavorativi. Il costo è di €50. Non è possibile effettuare il pagamento con contrassegno.