SIKAFLEX 290 DC BLACK 300ML 380GR (509181)

Couldn't load pickup availability

Sikaflex®-290 DC PRO

Sikaflex®-290 DC PRO is a one-component polyurethane sealant, specifically formulated for caulking joints in traditional wooden decking in the marine industry. It has excellent weather resistance and is therefore suitable for open joints exposed to high levels of marine environments. The sealing compound cures to a flexible elastomer which allows for a quick and easy sanding process. Sikaflex®-290 DC PRO meets the standards set by the International Maritime Organisation (IMO).

ADVANTAGES

- Excellent resistance to atmospheric agents

- Sturdy and long-lasting

- Quick and easy sanding

- Ideal smoothness for application

- Smoothable for a long time

- Unique look

- Resistant to fresh and salt water

Jobs

Sikaflex®-290 DC PRO is designed for caulking joints in traditional wood decking for boats, yachts and commercial shipbuilding. This product is suitable for experienced professional users only. Tests with actual substrates under real conditions should be performed to ensure adhesion and material compatibility.Packaging

| Cartridge | 300 ml |

|

Unipack |

600 ml |

| Hobbock | 23 l |

| Stem | 195 l |

Product Details

HARDENING MECHANISM

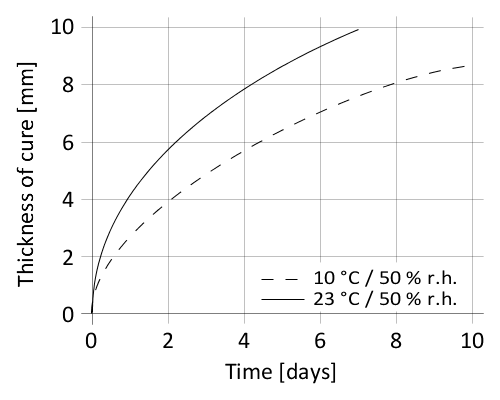

Sikaflex®-290 DC PRO cures by reaction with atmospheric moisture. At low temperatures the water content in the air is generally lower and the curing reaction proceeds more slowly (see diagram 1).

Diagram 1: Curing speed for Sikaflex®-290 DC PRO

CHEMICAL RESISTANCE

Sikaflex®-290 DC PRO offers effective long-term resistance to fresh water, sea water and water-based cleaning agents. The sealant is not resistant to solvents, acids, caustic solutions and chlorinated cleaners. Brief contact with fuels or lubricants has no significant effect on the durability of the sealant.

Application

Surface preparation

Surfaces must be clean, dry and free from grease, oil and dust. On wood, the use of a suitable primer, such as Sika® Primer-290 DC, is mandatory. Further surface treatments depend on the specific nature of the substrates, such as for the perimeter sealing of the deck. However, all recommendations must be determined by preliminary tests.

Application

To achieve satisfactory results the adhesive must be applied with suitable equipment such as pump systems, dosing units or piston application guns. Sikaflex®-290 DC PRO can be processed between 5 °C and 35 °C but variations in reactivity and application properties must be taken into account. The optimum process temperature (substrate, ambient and product) is between 15 °C and 25 °C.

Removal

Uncured Sikaflex®-290 DC PRO can be removed from tools and equipment with Sika® Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin must be washed immediately using hand cleaning wipes such as Sika® Cleaner-350H, or a suitable industrial hand cleaner and water. Do not use solvents on skin!

Le spedizioni per l'Italia avvengono in 2-6 giorni lavorativi. Il costo è di €9,99 per i pagamenti effettuati con carta e di €14,99 per pagamenti con contrassegno.

Le spedizioni per i paesi UE avvengono in 4-9 giorni lavorativi. Il costo è di €30. Non è possibile effettuare il pagamento con contrassegno.

Le spedizioni per i paesi Extra UE avvengono in 6-10 giorni lavorativi. Il costo è di €50. Non è possibile effettuare il pagamento con contrassegno.